HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

Bottom price Cryogenic Air Separation Plant/Liquid Nitrogen Plant/Oxygen Plant

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers’ demands for Bottom price Cryogenic Air Separation Plant/Liquid Nitrogen Plant/Oxygen Plant, We sincerely welcome you occur to visit us. Hope we now have very good cooperation from the potential.

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers’ demands for China Liquid Air Separation Plant and Liquid Oxygen Nitrogen Equipment, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

|

Product Name |

PSA Nitrogen Generator |

|

Model No. |

NZN ; NZN97; NZN99; NZN39; NZN49; NZN59 |

|

Oxygen Production |

5~3000Nm3/h |

|

Oxygen Purity |

P5~99.9995% |

|

Oxygen Pressure |

0~0.8Mpa (0.8~6.0MPa alternative) |

|

Dew Point |

≤-45 degree C ( Normal Pressure) |

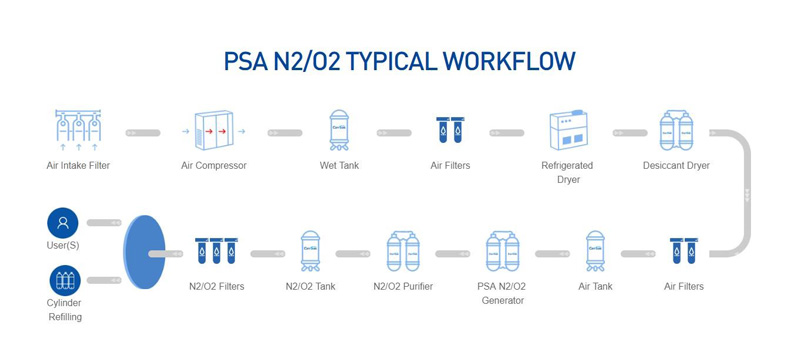

Pressure swing adsorption (PSA) process is made up two vessels filled with molecular sieves and activated alumina. Compressed air is passed through

vessel at 30 degrees C and oxygen is generated as a product gas. Nitrogen is discharged as an exhaust gas back into atmosphere. When the molecular sieve bed is saturated, the process is switched to the other bed by automatic valves for oxygen generation.

It is done while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Two vessels keep working alternately in oxygen production and regeneration allowing oxygen is available to the process.

1:The equipment has the advantages of low energy consumption, low cost, strong adaptability, fast gas production and easy adjustment

of purity.

2:Perfect process design and best use effect;

3:Modular design is designed to save land area.

4:The operation is simple, the performance is stable, the automation level is high, and it can be realized without operation.

5:Reasonable internal components, uniform air distribution, and reduce the high speed impact of airflow;

6:Special carbon molecular sieve protection measures to extend the life of carbon molecularsieve.

7:The key components of famous brands are the effective guarantee of equipment quality.

8:The automatic emptying device of national patent technology guarantees the nitrogen quality of finished products.

9: It has many functions of fault diagnosis, alarm and automatic processing.

10: Optional touch screen display, dew point detection, energy saving control, DCS communication and so on.

IF YOU HAVE ANY INTERSTS TO KNOW MORE INFORMATION, CONTACT US: 0086-18069835230

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers’ demands for Bottom price Cryogenic Air Separation Plant/Liquid Nitrogen Plant/Oxygen Plant, We sincerely welcome you occur to visit us. Hope we now have very good cooperation from the potential.

Bottom price China Liquid Air Separation Plant and Liquid Oxygen Nitrogen Equipment, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.