HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO China Cryogenic Oxygen Plant For Steel Smelting High Purity 99.6% Liquid Oxygen Metallurgical Plant

Specification :

|

Product Name |

Cryogenic air separation equipment |

|

Model No. |

NZDON- 50/60/80/100/120CUSTOMIZED |

|

Brand |

NuZhuo |

|

Accessories |

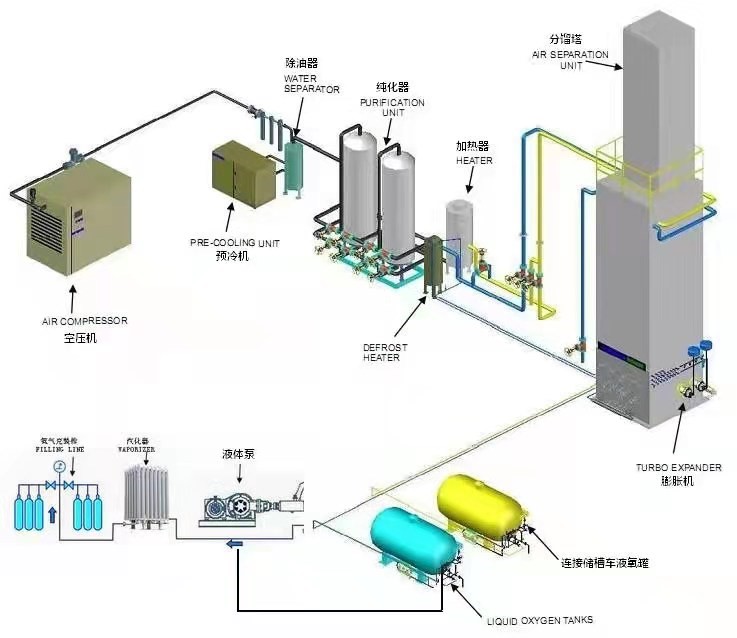

Air compressor & Re- cooling system & Expander&Cold box |

|

Usage |

High purity Oxygen & Nitrogen & Argon production machine |

The cryogenic oxygen production & oxygen&nitrogen production process introduces a low-pressure process into the air separation equipment, which reduces the energy consumption of the air separation and improves the safety of operation. Corresponding chemical software is used in process calculation and unit equipment design for process distillation calculation and structure calculation to ensure advanced and reliable equipment.

In order to meet the needs of the market, in addition to the production of conventional external compression air separation equipment, the company has also developed a series of internal compression air separation processes, which reduces the installation workload and equipment maintenance of the complete set of equipment.

The company designed and developed a skid-mounted purification system to minimize on-site piping installation time

|

Model |

NZDON-50/50 |

NZDON-80/160 |

NZDON-180/300 |

NZDON-260/500 |

NZDON-350/700 |

NZDON-550/1000 |

NZDON-750/1500 |

NZDON-1200/2000/0y |

|

O2 0utput (Nm3/h) |

50 |

80 |

180 |

260 |

350 |

550 |

750 |

1200 |

|

O2 Purity (%O2) |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

≥99.6 |

|

N2 0utput (Nm3/h) |

50 |

160 |

300 |

500 |

700 |

1000 |

1500 |

2000 |

|

N2 Purity (PPm O2) |

9.5 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

≤10 |

|

Liquid Argon Ouput ( Nm3/h) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

30 |

|

Liquid Argon Purity ( Ppm O2 + PPm N2) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

≤1.5ppmO2 + 4 p p mN2 |

|

Liquid Argon Purity ( Ppm O2 + PPm N2) |

—— |

—— |

—— |

—— |

—— |

—— |

—— |

0.2 |

|

Consumption (Kwh/Nm3 O2) |

≤1.3 |

≤0.85 |

≤0.68 |

≤0.68 |

≤0.65 |

≤0.65 |

≤0.63 |

≤0.55 |

|

Occupied Area (m3) |

145 |

150 |

160 |

180 |

250 |

420 |

450 |

800 |

The role of cryogenic technology in steel smelting:

The main industrial application of oxygen is combustion support. Many materials that are not normally combustible in air can combust in oxygen, so mixing oxygen with air greatly improves combustion efficiency in the steel, non-ferrous, glass and concrete industries. When mixed with fuel gas, it is widely used in cutting, welding, brazing and glass blowing, providing higher temperature than air combustion, thus improving efficiency. Along with oxyfuel, plasma and laser processes, jets of gaseous oxygen can be used to cut steel. Oxygen is also commonly used for hot seam drilling or cutting materials such as concrete, brick, stone and various metals.

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.