HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO China Factory Industrial Oxygen Plant Air Separation Unit

Description of Cryogenic Air separation Unit :

|

Product Type: |

cryogenic air separation plant |

|

Oxygen purity : |

99.6% |

|

Nitrogen purity: |

99.999% |

|

Warranty time: |

18 months |

|

Service : |

Engineer oversea service available |

|

Payment term: |

T/T and L/C as sign |

|

Design: |

As your request |

|

Deliverty term: |

CIF , FOB, CFR... |

Cryogenic O2 pant (>99%)

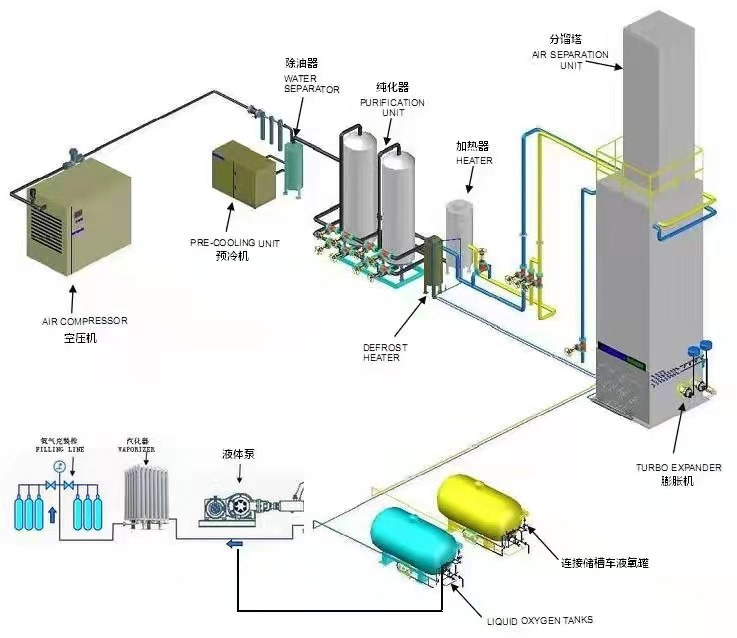

Cryogenic oxygen plant or called air Separation Unit (ASU) can generate only oxygen, or generate both oxygen and nitrogen in gas or liquid form. The working principle of it is that dry saturated air with purifications to remove moisture, impurities entering the lower tower becomes liquid air as it continues to be cryogenic. Physically air is separated, and high purities oxygen and nitrogen are obtained by rectifying in fractionating column according to different boiling points of them. Rectifying is the process of multiple partial evaporation and multiple partial condensation.

This kind of cryogenic oxygen plant has main components including rectifying tower or cooling tower, air compressor, pre-cooler, turbine expander etc.

Flow chart:

We can design and produce according to our customers’request and the climate in different countries.

FAQ:

- What are the maintenance cost of each gas machine?

Different types have different components and maintenance cost. For the same type different sizes and performances are also different.

Take PSA oxygen generators for example, the maintenance parts mainly include air compressors, filters, and oxygen compressors if any.

- What happens if maintenance is not done well?

Firstly if overly water, oil vapor, dust enter some parts absorbent like molecular sieve, these parts shall have to replaced completely. Subsequently this will affect performances of machines.

So regular maintenance is an important work to do, like replacing filter elements every 2,000 -4,000 hours.

- Which method and type are the most economical?

It depends on how much gas required and its quality requirements. Different types have their advantages.

- What are the utility requirements for a system?

Generally electricity power is required by each system, and some requires cooling water also. The power consumption varies from small to big sizes. For unit power consumption, normally the bigger size the less unit power consumption.

- What output pressure can gas plant produce?

Different type has different normal pressures from 0.5 to 20bar. With compressor added any desired pressures are available.

For example PSA nitrogen generator gets 1-8bar, or 150bar with added nitrogen compressor.

- What purity oxygen & nitrogen plant can achieve?

O2 range: 90%-99.9%.

N2 range: 95%-99.9999%

- Can flow and purity be changed?

Yes available. By touching screen all parameters are regulated.

- Is it dangerous for filling high pressure oxygen bottles?

Following the manual and notice to do operation is safe. Very rare there are blast for filling cylinders, unless wrong operations or poor quality of high pressure parts.

- Can our local manufacture standards be followed?

Generally available. We can design and manufacture as per your country's law or regulation, like US standards ASME, CE standards PED etc.

- Can the system be monitored and controlled by PC and mobile phone?

Yes available. Complete monitoring of working parameters like flow, purity and alarms/reminders are within our capability. We have cloud monitoring to utilize cloud technology for the system.

- Are onsite services available ?

Yes it is. Engineers can be sent to customers site for installation, startup, commissioning, training. Service charge USD150/day excluding travel cost.

- How long to finish installation ?

Different types have different time. PSA unit takes normally 3-7 days to finish installation, startup, commissioning, training.

Cryogenic unit takes longer time, generally a month.

It also has to do with site preparation conditions and workers proficiency.

- What is your payment term accepted?

20-30% down payment, balance done before or after shipment or by irrevocable L/C.

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.