-

NUZHUO High Purity Cryogenic Liquid Nitrogen Generator Small Food Nitrogen Gas Plants 20L/h

LN2 flow: 5-50L/h

LN2 purity: 99~99.999%

Key Selling Points: Energy saving

-

NUZHUO Small and Medium Cryogenic Air Separation Plant With High Efficiency Low Power Consumption Oxygen Nitrogen Grgon Generator

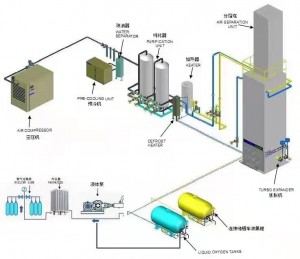

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO High Purity Oxygen Plant Manufacturer Cryogenic Air Separation Liquid Oxygen Plant

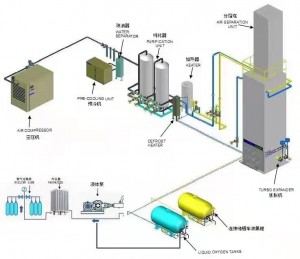

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Liquid Oxygen Production Line Cryogenic Liquid Nitrogen Production Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO 10TPD NZDO-300 Air Separation Plant Liquid Oxygen Plant Medical Oxygen Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Nitrogen Cryogenic Plant Air Separation Unit N2 Generator System Cryogenic Oxygen Plant Liquid

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Medicinal Oxygen Plant For Hospital 220Nm3/H Liquid Oxygen Producing Plant For Steel Scrap

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO China Cryogenic Oxygen Plant For Steel Smelting High Purity 99.6% Liquid Oxygen Metallurgical Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Cyogenic Oxygen Air Separation Plant Medical Oxygen Generator Plant With Cylinder Filling Station

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Cryogenic ASU Oxygen and Nitrogen Air Separation Unit Gaseous And Liquid Productions Simultaneously

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO High Quality Liquid Oxygen Plant Air Separation Plant Made In China

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Industrial Liquid Oxygen Production Plant O2 Liquid Plants Air Separation Unit Manufactures

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

Phone:

0086-15531448603

Phone:

0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com