HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

NUZHUO High Purity Cryogenic Liquid Nitrogen Generator Small Food Nitrogen Gas Plants 20L/h

Specifications for the Liquid Nitrogen generator :

|

Product Name |

Liquid oxygen & nitrogen generator |

|

Model No |

KDON- 5/10/20/40/60/80/CUSTOMIZED |

|

Brand |

NuZhuo |

|

Accessories |

Air compressor & Re- cooling system & Expander |

|

Usage |

High purity Oxygen & Nitrogen & Argon production machine |

With our liquid nitrogen generators, you can "produce" your own liquid nitrogen (LN2) without having to buy it, with great convenience, a stable supply of LN2, and many more. A continuous supply of LN2 is possible by connecting our liquid nitrogen generators directly to your LN2 cooled cryogenic reservoir. In addition, with backup power, LN2 can continue to be supplied even in the event of power outages caused by natural disasters. This makes it possible to cryopreserve important biological samples in a stable and reliable manner. Our liquid nitrogen generators are now widely used to cool IPS cells, tissues, vaccines or cryogenic storage of livestock fertilized eggs.

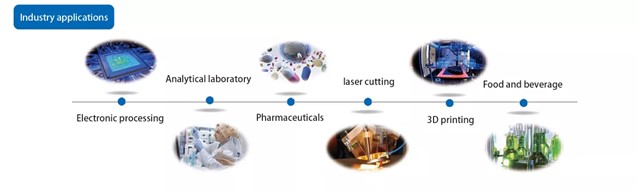

Oxygen, nitrogen, argon and other rare gas produced by air separation unit are widely used in steel, chemical industry,refinery,glass, rubber, electronics, healthcare, food, metals, power generation and other industries.

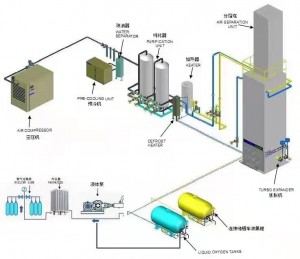

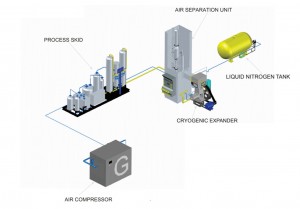

1. Air Compressor : Air is compressed at a low pressure of 5-7 bar (0.5- 0.7 mpa). It is done by using the latest compressors (Screw/Centrifugal Type).

2. Pre Cooling System : The second stage of the process involves use of a refrigerant for pre-cooling the processed air to temperature around 12 deg C before it enters the purifier.

3. Purification of Air By Purifier : The air enters a purifier, which is made up of twin molecular Sieve driers that function alternatively.The Molecular Sieve separates the carbon dioxide& moisture from the process air before the air reaches at air separation Unit.

4. Cryogenic Cooling of Air By expander : The air must be cooled to sub zero temperatures for liquefaction. The cryogenic refrigeration and cooling is provided by a highly efficient turbo expander, which cools the air to temperature below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column : The air that enters the low pressure late fin type heat exchanger is moisture free, oil free and carbon dioxide free. It is cooled inside the heat exchanger below sub zero temperatures by air expansion process in the expander. It is expected that we achieve a difference delta as low as 2 degree Celsius at the warm end of exchangers. Air gets liquefied when it reaches at the air separation column and is separated into oxygen and nitrogen by the process of rectification.

6. Liquid Oxygen is Stored in a Liquid Storage Tank : Liquid oxygen is filled in a liquid storage tank that is connected to the liquefier forming an automatic system. A hose pipe is used for taking out liquid oxygen from the tank.

Our company :

We are Hangzhou Nuzhuo Group, we believe we will be your supplier and partner with good service and high quality in China.

Our main business: PSA oxygen generator, nitrogen generator, VPSA industrial oxygen generator, cryogenic air separation series, and valve production.

We are committed to advancing the development of industrial and medical gases.If you want to purchase our equipment in the near future, or want to become our agent abroad, you can contact us, we will provide you with our best service.

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.

Phone:

+86-18069835230

Phone:

+86-18069835230 E-mail:lyan.ji@hznuzhuo.com

E-mail:lyan.ji@hznuzhuo.com