HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

High Quality for Vpsa Oxygen Plant - Oxygen Machine Oxygen Production Plant 200m3 Capacity Medical PSA Oxigen Generators Supplier – Nuzhuo

High Quality for Vpsa Oxygen Plant - Oxygen Machine Oxygen Production Plant 200m3 Capacity Medical PSA Oxigen Generators Supplier – Nuzhuo Detail:

|

Product Name |

PSA Oxygen Generator Plant |

|

Model No. |

NZO- 3/5/10/15/2025/30/40/50/60/CUSTOMIZED |

|

Oxygen Production |

5~200Nm3/h |

|

Oxygen Purity |

70~93% |

|

Oxygen Pressure |

0~0.5Mpa |

|

Dew Point |

≤-40 degree C |

|

Component |

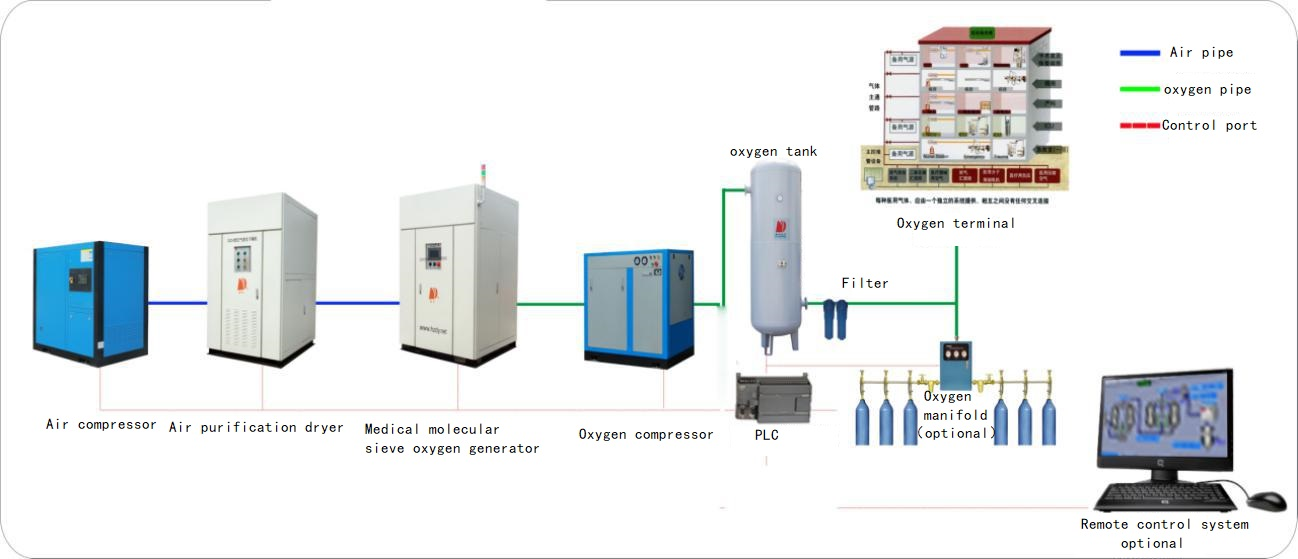

Air compressor, Air purification system, PSA oxygen generator, booster, filling manifold etc |

|

Specification |

Output (Nm3/h) |

Effective gas consumption ( Nm3/h ) |

Air cleaning system |

|

NZO-5 |

5 |

1.3 |

CJ-2 |

|

NZO-10 |

10 |

2.5 |

CJ-3 |

|

NZO-20 |

20 |

5 |

CJ-6 |

|

NZO-40 |

40 |

9.5 |

CJ-10 |

|

NZO-60 |

60 |

14 |

CJ-20 |

|

NZO-80 |

80 |

19 |

CJ-20 |

|

NZO-100 |

100 |

22 |

CJ-30 |

|

NZO-150 |

150 |

32 |

CJ-40 |

|

NZO-200 |

200 |

46 |

CJ-50 |

We manufacture PSA oxygen plant using the latest PSA (Pressure Swing Adsorption) technology. Being the leading PSA oxygen plant manufacturer, it is our motto to deliver oxygen machinery to our customers that is at par with international standards and yet is very competitively priced. We use premium quality materials bought from the best suppliers in the industry. Oxygen generated in our PSA oxygen generator meets the requirements of industrial as well as medical applications. Numerous companies from around the globe are using our PSA oxygen plant and are generating oxygen on-site for running their operations.

1.Simple installation and maintenance thanks to modular design and construction.

2.Fully automated system for simple and reliable operation.

3.Guaranteed availability of high-purity industrial gases.

4.Guaranteed by the availability of product in liquid phase to be stored for use during any maintenance operations.

5.Low energy consumption.

6.Short time delivery.

1. The equipment employs non-unipotential pressure-equalizing processes until consumption of compressed air is reduced directly.

2. We can select the most energy-saving molecular sieve according to customers’ conditions.

3. Advanced load adaptive technology to further reduce energy consumption.

4. Advanced packing technology to make carbon molecular sieve more compact and uniform and minimize friction coefficient.

IF YOU HAVE ANY INTERSTS TO KNOW MORE INFORMATION, CONTACT US: 0086-18069835230

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for High Quality for Vpsa Oxygen Plant - Oxygen Machine Oxygen Production Plant 200m3 Capacity Medical PSA Oxigen Generators Supplier – Nuzhuo , The product will supply to all over the world, such as: Cape Town, Swedish, USA, Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Product Categories

Focus on providing mong pu solutions for 5 years.