NUZHUO has always been aiming at the international markets, and making great efforts in developing ASU General Contracting and Investment exportation. HANGZHOU NUZHUO is one of the leading enterprises in gas producing industry in scientific research, design, consultation. service, integrated solutions, manufacture, marketing, completion of engineering project, equipment installation and commissioning etc. The ASU of NUZHUO, is capable of supplying Cryogenic Air Separation Plants all scales of ASU from 50 Nm3/h to 30,000 Nm3/h as one single unit. Since 1998, we have produced more than 20 sets of large & medium size ASUs, in which, the largest capacity of oxygen is 12,000 Nm3 per hour. In addition to producing of oxygen, nitrogen and argon in the large air separation plant, satisfying customers’ various demands.

NUZHUO has always been aiming at the international markets, and making great efforts in developing ASU General Contracting and Investment exportation. HANGZHOU NUZHUO is one of the leading enterprises in gas producing industry in scientific research, design, consultation. service, integrated solutions, manufacture, marketing, completion of engineering project, equipment installation and commissioning etc. The ASU of NUZHUO, is capable of supplying Cryogenic Air Separation Plants all scales of ASU from 50 Nm3/h to 30,000 Nm3/h as one single unit. Since 1998, we have produced more than 20 sets of large & medium size ASUs, in which, the largest capacity of oxygen is 12,000 Nm3 per hour. In addition to producing of oxygen, nitrogen and argon in the large air separation plant, satisfying customers’ various demands.

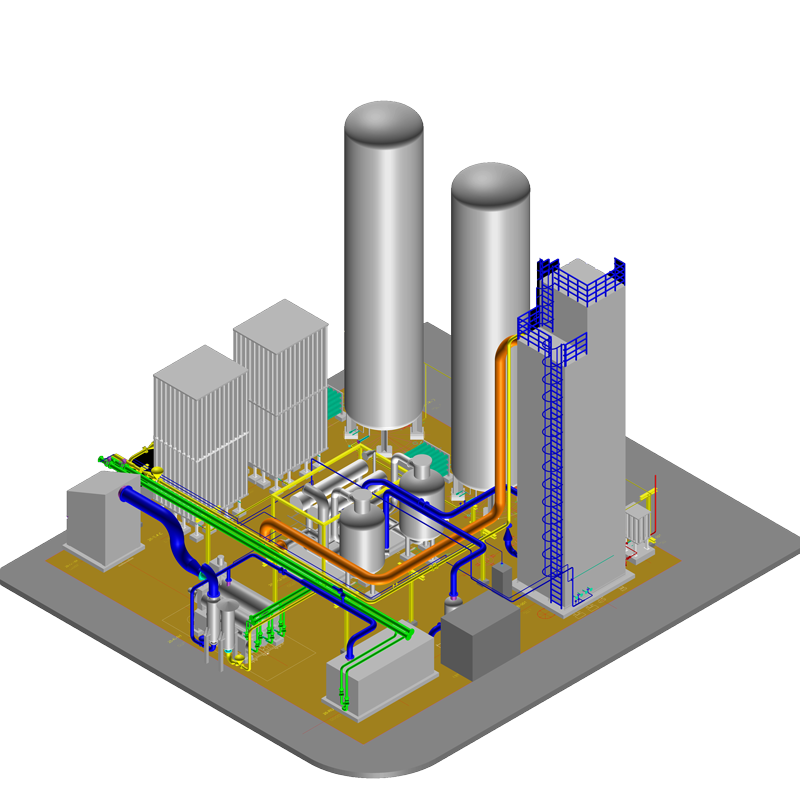

INTERNAL COMPRESSION PROCESS

LOX is pumped and vaporized in the cold box and send to user as GOX products. Such kind of process is especially used to meet the customer’s large demand of liquid product and the requirement for the high pressure of oxygen and nitrogen products in the chemical industry. Technology of molecular sieve pre-purification, high/medium pressure Heat exchangers, structural packing upper column and full rectification argon recovery is used in the air separation unit with such process, which has got the features of stable reliable and safe operation, big output of liquid product, high pressure of oxygen and nitrogen products with different level as required.

EXTERNAL COMPRESSION PROCESS

A typical kind of process that the low-pressure oxygen is produced by the plant and then compressed by the oxygen turbo compressor to the required pressure as the oxygen product. Such kind of process is specially applied in the metallurgical industry for the requirements that oxygen pressure is ≤3.0Mpa (G) and the demand of liquid product is not much. The technology of molecular sieve pre-purification, full low-pressure Heat exchangers, expanded air to the upper column, structural packing upper column and full rectification argon recovery are used in such process, which has got the features of strong variable-load capability; stable and reliable running, flexible and convenient operation, more homemade parts and accessories and lower investment cost.

Applications

We serve customers in a wide range of industries. Our accumulated practical experience allows us to design and deliver the perfect fit to meet your individual needs based on your industry recommendations. Our reference range includes:

Metals

• Iron and steel

Energy and Gasification

• IGCC, biomass and coal gasification, oxyfuel, natural gas, synthetic fuel, partial oxidation, coal-to-liquid, gas-to-liquid

Chemicals

• Ethylene oxide, NH₃ synthesis, petrochemicals

Post time: May-25-2022