Working principle

The basic principle of air separation is to use deep cold distillation to condense air into liquid, and separate according to the different boiling point temperatures of oxygen, nitrogen and argon.

The two-stage distillation tower obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower at the same time.

Liquid oxygen and liquid nitrogen can also be taken out from the evaporation side and condensation side of the main cooling respectively.

The air separation of the distillation tower is divided into two stages. The air is separated for the first time in the lower tower to obtain liquid nitrogen, and oxygen-rich liquid air is obtained at the same time.

The oxygen-rich liquid air is sent to the upper tower for distillation to obtain pure oxygen and pure nitrogen.

The upper tower is divided into two sections: the upper section is the distillation section with the liquid and gas inlet as the boundary, which distills the rising gas, recovers the oxygen component, and improves the purity of nitrogen; the lower section is the stripping section, which removes the nitrogen component in the liquid, separates, and improves the oxygen purity of the liquid.

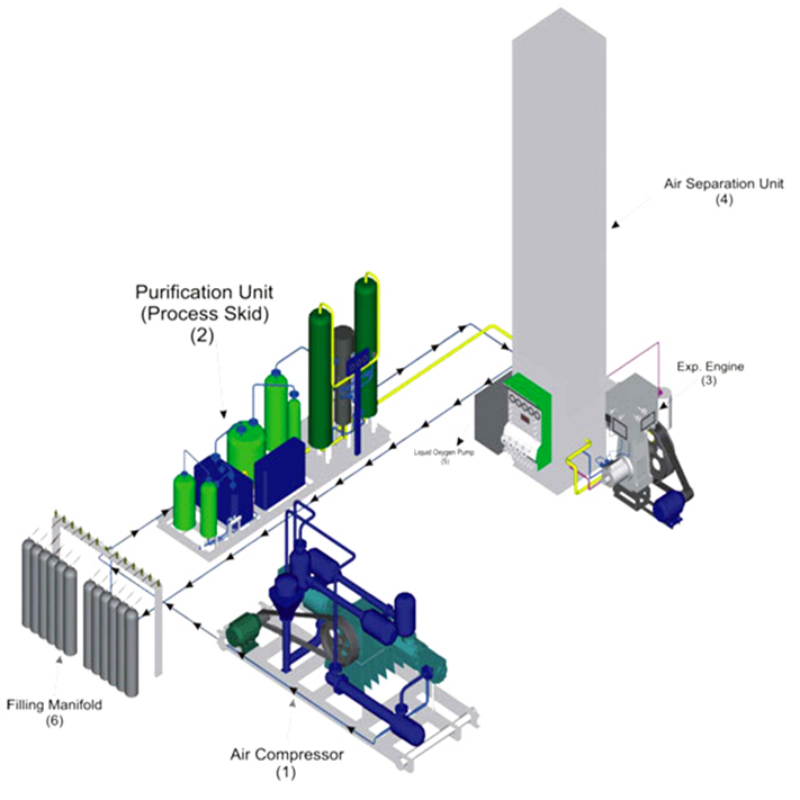

Process flow

1. Air compression: The air that has been filtered out of mechanical impurities by the filter enters the air compressor and is compressed to the required pressure.

2. Air precooling: It is cooled to a suitable temperature in the precooling system and free water is separated at the same time

3. Air separation purification: Water, carbon dioxide and other hydrocarbons are removed by adsorbents in the adsorption tower.

4. Fractionation tower cold box: Clean air enters the cold box, is cooled to a temperature close to the liquefaction temperature through the heat exchanger, and then enters the distillation tower. The product nitrogen is obtained in the upper part and the product oxygen is obtained in the lower part

For any oxygen/nitrogen/argon needs, please reach out to us :

Emma Lv Tel./Whatsapp/Wechat:+86-15268513609

Email:Emma.Lv@fankeintra.com

Post time: Apr-15-2025