1. Oxygen

The main production methods of industrial oxygen are air liquefaction separation distillation (referred to as air separation), hydroelectricity and pressure swing adsorption. The process flow of air separation to produce oxygen is generally: absorbing air → carbon dioxide absorption tower → compressor → cooler → dryer → refrigerator → liquefaction separator → oil separator → gas storage tank → oxygen compressor → gas filling. The basic principle is that after the air is liquefied, the different boiling points of each component in the air are used for separation and rectification in the liquefaction separator to produce oxygen. The research and development of large oxygen generating units has reduced the energy consumption of oxygen production, and it is easy to produce a variety of air separation products (such as nitrogen, argon and other inert gases) at the same time. In order to facilitate storage and transportation, the liquid oxygen separated by the liquefaction separator is pumped into the cryogenic liquid storage tank, and then transported to each cryogenic liquefied permanent gas filling station by tank truck. Liquid nitrogen and liquid argon are also stored and transported in this way.

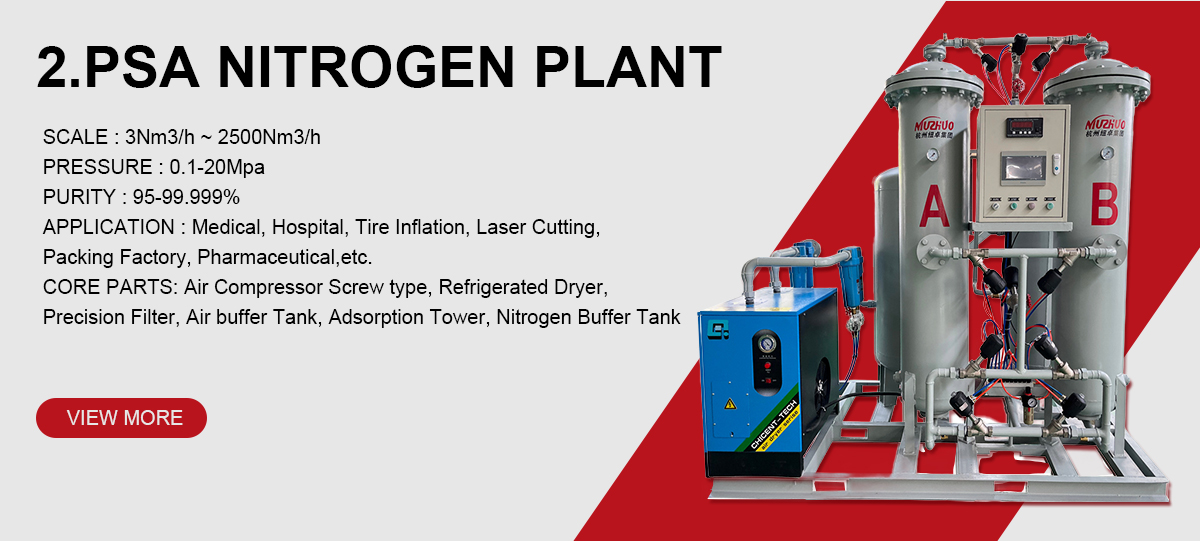

2. Nitrogen

The main production methods of industrial nitrogen include air separation method, pressure swing adsorption method, membrane separation method and combustion method.

The nitrogen obtained by air separation method has high purity and low energy consumption. Pressure swing adsorption nitrogen technology is the use of 5A carbon molecular sieve for selective adsorption of components in the air, the separation of oxygen and nitrogen to produce nitrogen, nitrogen product pressure is high, low energy consumption, product purity can meet the national standards: industrial nitrogen ≥98.5%, pure nitrogen ≥99.95%

3.Argon

Argon is the most abundant inert gas in the atmosphere, and the main production methods are air separation. In the process of oxygen production, liquid argon is obtained by separating the fraction with boiling point of -185.9℃ from the liquefaction separator.

For any oxygen/nitrogen needs, please reach out to us :

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Post time: Apr-14-2025