HANGZHOU NUZHUO TECHNOLOGY GROUP CO.,LTD.

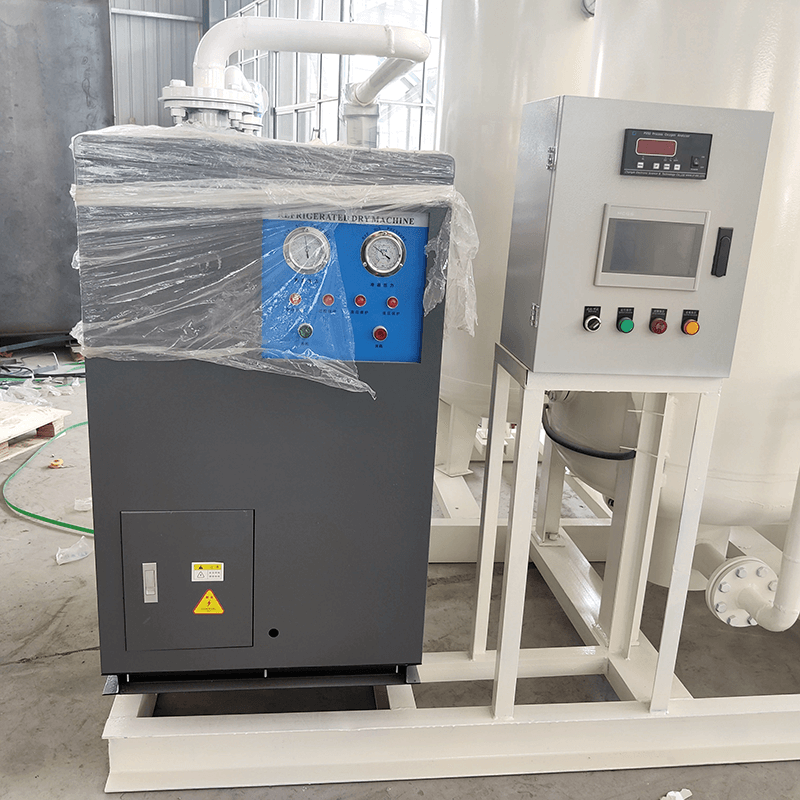

NUZHUO Oxygen Plant PSA Oxygen Generator With Capacity Of 25Nm3/H 150 Bar Pressure Filling Cylinder

The company's products take compressed air as raw material, through the automated process, compressed air purification, separation, extraction. The company owns six series of cryogenic air separation equipment, compressed air purification equipment, PSA PSA adsorption air separation equipment, nitrogen and oxygen purification equipment, membrane separation air separation equipment and VPSA oxygen production equipment, with more than 200 kinds of specifications and models.

|

Specification |

Output (Nm3/h) |

Effective gas consumption ( Nm3/h ) |

Air cleaning system |

|

XSO-5 |

5 |

1.3 |

CJ-2 |

|

XSO-10 |

10 |

2.5 |

CJ-3 |

|

XSO-20 |

20 |

5 |

CJ-6 |

|

XSO-40 |

40 |

9.5 |

CJ-10 |

|

XSO-60 |

60 |

14 |

CJ-20 |

|

XSO-80 |

80 |

19 |

CJ-20 |

|

XSO-100 |

100 |

22 |

CJ-30 |

|

XSO-150 |

150 |

32 |

CJ-40 |

|

XSO-200 |

200 |

46 |

CJ-50 |

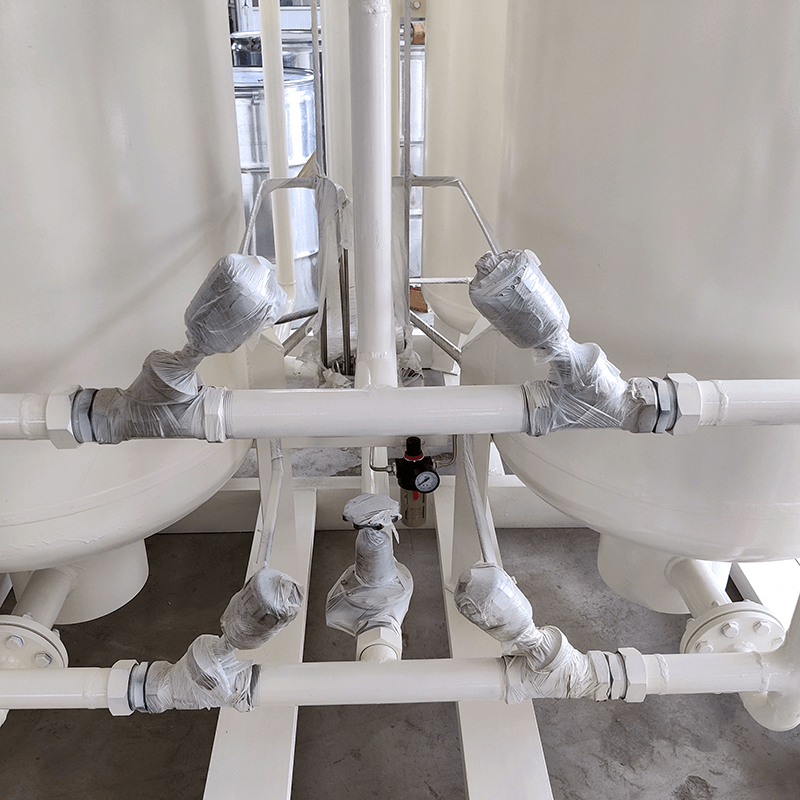

1. For the same adsorbed gas (adsorbate) in any adsorprtion, the lower temperature, the higher pressure and the larger adsorbing capacity

2. when absorption remains stable; otherwise, the higher temperature, the lower pressure and the smaller adsorbing capacity. If the temperature remains unchanged, desorption with decompression (vacuum pumping) or under normal pressure is called pressure swing adsorption (PSA) in the event of adsorption under compression.

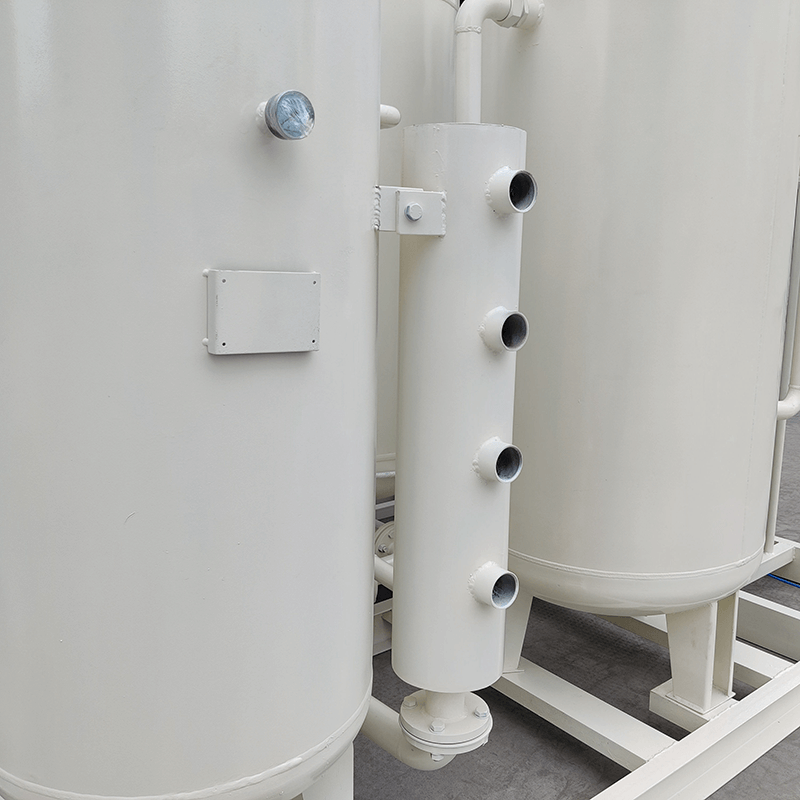

3. As shown above, the size of adsorption of oxygen and nitrogen by carbon molecular sieve varies largely. Nitrogen and oxygen can be separated due to the size difference of oxygen and nitrogen adsorption from the air under some pressure. When the pressure rises,carbon molecular sieve adsorbs oxygen and generates nitrogen; when the pressure falls to normal, the sieve desorbs oxygen and regenerates nitrogen. Usually, the PSA nitrogen generator has two adsorbers, one of which adsorbs oxygen and produces nitrogen, and the other desorbs oxygen and regenerates nitrogen. In this way, nitrogen is produced continuously.

1. The equipment employs non-unipotential pressure-equalizing processes until consumption of compressed air is reduced directly.

2. Ae can select the most energy-saving molecular sieve according to customers' conditions.

3. Advanced load adaptive technology to further reduce energy consumption.

4. Advanced packing technology to make carbon molecular sieve more compact and uniform and minimize friction coefficient.

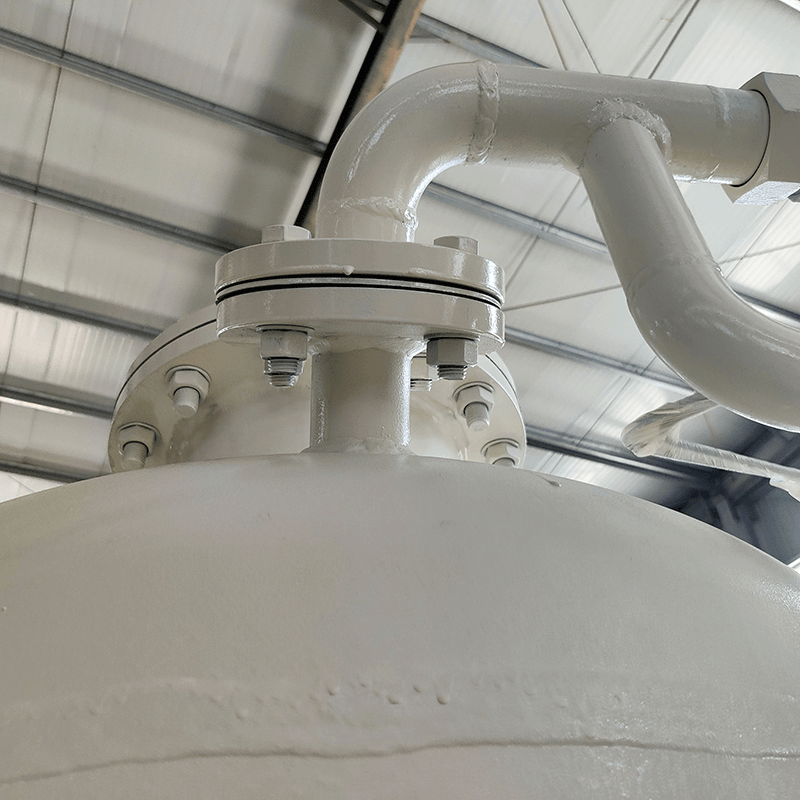

5. Most reliable gas supply treatment to ensure adsorption efficiency and service life of the sieve.

6. Switchover valves and components of famous brands employed to ensure product quality.

7. Advanced automatic cylinder compaction technology.

8. The equipment can be monitored on a real-time.

9. Ineligible nitrogen can be emptied automatically.

10. Friendly HMI.

If you have any intersts to know more information, contact us: 0086-18069835230

Company Profile

Certificate & NUZHUO

Q1: Are you a trading company or manufacturer?

Q3: How long is your delivery time?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: What is your product quality assurance policy?

Q5: Do you offer OEM/ODM service?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Does your product used or new? RTS product or customized product?

Product Categories

Focus on providing mong pu solutions for 5 years.