-

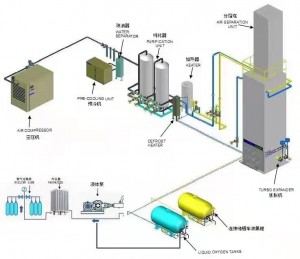

NUZHUO Liquid Oxygen Production Line Cryogenic Liquid Nitrogen Production Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO 10TPD NZDO-300 Air Separation Plant Liquid Oxygen Plant Medical Oxygen Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

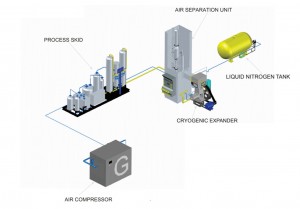

NUZHUO Nitrogen Cryogenic Plant Air Separation Unit N2 Generator System Cryogenic Oxygen Plant Liquid

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

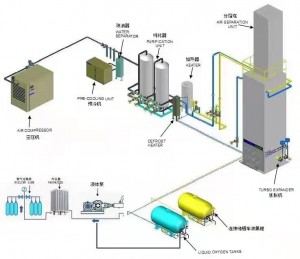

NUZHUO Medicinal Oxygen Plant For Hospital 220Nm3/H Liquid Oxygen Producing Plant For Steel Scrap

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO China Cryogenic Oxygen Plant For Steel Smelting High Purity 99.6% Liquid Oxygen Metallurgical Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Cyogenic Oxygen Air Separation Plant Medical Oxygen Generator Plant With Cylinder Filling Station

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

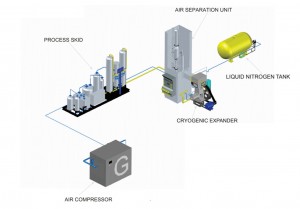

NUZHUO Cryogenic ASU Oxygen and Nitrogen Air Separation Unit Gaseous And Liquid Productions Simultaneously

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO High Pressure Air Cooling Oil Free Oxygen Booster Oxygen Cylinder Filling Station Oxygen Compressor

Flow:3-200m3/h

Inlet Pressure: 0.4MPA( G )

Exhaust Pressure: 150bar,200bar( adjustable)

Power consumption: 3-44KW/AC power

Oil free Piston Type

Gas compressor: O2, N2,H2, SF6, CO2, He, Ar, Air

-

NUZHUO High Quality Liquid Oxygen Plant Air Separation Plant Made In China

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Industrial Liquid Oxygen Production Plant O2 Liquid Plants Air Separation Unit Manufactures

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO NZDO-50 Cryogenic Oxygen Air Separation Full Automatic Control Cryogenic Oxygen Plant

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank

-

NUZHUO Cryogenic ASU Liquid Oxygen Nitrogen Production Line Air Separation Unit

1. Air Compressor: Air is compressed at a low pressure of 5-7 bar (0.5-0.7mpa)

2. Pre Cooling System: Cooling the temperature of air to around 12 deg C.

3. Purification of Air By Purifier: Twin molecular Sieve driers

4. Cryogenic Cooling of Air by Expander: Turbo expander cools the temperature of air below -165 to-170 deg C.

5. Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column

6. Liquid Oxygen/Nitrogen is stored in a Liquid Storage Tank